Feb 11, 2026

Simon L.

8min Read

Ecommerce inventory management is the system and processes you use to track, control, and optimize your stock levels across your entire online business.

It’s how you know what you have, where it is, when to order more, and how to get products into customers’ hands efficiently.

It encompasses real-time stock tracking, seamless order fulfillment, accurate demand forecasting, and tight supplier coordination to keep everything flowing smoothly.

Here’s the challenge for online retailers: you’re juggling inventory across multiple warehouses, managing returns and new orders simultaneously, and predicting demand without foot traffic patterns.

The sweet spot is having just enough inventory to meet customer demand without tying up too much capital in stock.

Too little means lost sales and disappointed customers. Too much means cash sitting idle, mounting storage fees, and potential markdowns. Master this balance, and you’re set up for sustainable, profitable growth.

Ecommerce inventory management is important because it directly impacts your bottom line, shapes your customer experience, and determines whether you’re running a profitable business or just spinning your wheels.

It protects your profits

Good inventory control is like having a financial superpower. When you keep popular items in stock, you capture every sale opportunity.

On the flip side, smart inventory management means you’re not tying up your capital in products that sit gathering dust or paying unnecessary storage fees.

Finding the balance between too little and too much is where the magic happens. With the right systems in place, it’s totally achievable.

For example, if you sell candles and your bestselling scent typically moves 200 units during the holidays, stocking only 150 means missing 50 sales. Ordering 400 means capital sitting in your warehouse until next December.

It improves ecommerce customer service

Customers want their order to be accurate, complete, and delivered quickly, and when you nail your inventory management, you can absolutely deliver on those expectations.

With solid inventory control, you can:

It lets you scale

Look at how successful ecommerce businesses operate. Whether it’s a small boutique tracking 100 SKUs or a larger retailer managing thousands, sophisticated inventory systems help them predict demand accurately and deliver products quickly.

The good news? These tools are more accessible and affordable than ever.

When you’re starting an ecommerce business, getting your inventory management right from day one sets you up for sustainable growth instead of constant crisis management.

Inventory management is a continuous cycle that helps you keep just the right amount of stock on hand to avoid both shortages and excess.

This is where you put on your fortune-teller hat, except instead of a crystal ball, you’re using data.

Planning and forecasting involve analyzing your historical sales patterns, seasonal trends, market conditions, and upcoming promotions to predict what you’ll need and when.

What the work involves:

This results in a solid demand forecast that tells you how much of each product you’ll need, helping you avoid running out of best-sellers during peak season or over-ordering products that don’t sell.

Armed with your forecast, it’s time to actually buy the stuff you’re going to sell.

This stage involves working with suppliers to place orders, negotiating terms and pricing, coordinating delivery schedules, and managing your budget to balance inventory investment with cash flow.

What the work involves:

You get the right quantity of products ordered at the right price, with delivery timed to meet your anticipated demand. This means no overflowing your warehouse space or draining your bank account before sales come in.

Your products have arrived, but you’re not done yet. This stage requires attention to detail as you physically process everything coming through your doors.

What the work involves:

You’ll have accurate records showing exactly what you have on hand, with products properly stored and ready for fulfillment.

Now that your inventory is in storage, you need to monitor it actively. This lets you see exactly what you have, where it is, and when it’s time to reorder.

What the work involves:

This lets you see everything in your inventory at all times, along with actionable insights into which products are performing well and which aren’t pulling their weight.

Now you’re getting products to customers. Every sale triggers a chain of activities that needs to happen quickly and accurately.

What the work involves:

You’ll have orders fulfilled accurately and quickly, inventory counts automatically updated to reflect what’s been sold, and happy customers receiving exactly what they ordered.

And we’re back to the beginning, almost. As inventory sells down, you need to replenish it before you hit zero. This stage closes the loop and keeps the cycle running smoothly.

What the work involves:

You’ll replenish stock smoothly to keep shelves stocked without over-ordering, balancing enough inventory to meet demand without tying up excess capital.

Ecommerce inventory management methods involve different strategic approaches for controlling stock levels, optimizing ordering, and maximizing efficiency.

Think of these as your toolkit. You’ll probably use several of them together, depending on your business needs.

Demand forecasting uses your sales history, market trends, and statistical models to predict what customers will want next. You’re essentially looking at patterns from the past to anticipate the future.

If your data shows beach towels spike 250% every June, you’ll order ahead instead of scrambling mid-season.

Best for: Any business with enough sales history. This is your foundation. Pair it with pretty much everything else to make smarter decisions across the board.

Just-In-Time means you receive products only when you need them for immediate sale, keeping almost nothing in storage by coordinating closely with suppliers.

Best for: Businesses with reliable suppliers and steady demand. Works great with demand forecasting, but it’s the opposite of safety stock (which is all about keeping extra inventory). If your demand is unpredictable or suppliers are unreliable, skip this one.

FIFO (First-In-First-Out) means selling your oldest inventory first. LIFO (Last-In-First-Out) means selling your newest inventory first.

Best for: Go with FIFO for ecommerce, especially if you sell anything with expiration dates, seasonal products, or items that can go out of style. LIFO might save on taxes when costs are rising, but it leaves old stock gathering dust and isn’t even allowed under international accounting standards (though it’s still permitted under US GAAP). Pick one and stick with it.

In ABC analysis, you sort inventory into three tiers. A items are your revenue champions (usually 20% of products driving 80% of revenue), B items are your steady performers, and C items are your lower-value products.

For example, if you sell skincare products, your vitamin C serum might be an A item generating 40% of revenue, while sheet masks are C items bringing in just 2%.

Best for: Anyone selling more than a handful of products. This is your decision-making framework. Use it to figure out where to apply other methods. Maybe use safety stock for A items, JIT for C items, and EOQ for B items.

Safety stock is the extra inventory you keep as a buffer against surprises like demand spikes, supplier delays, or forecasting hiccups. You calculate how much based on how variable your lead times and demand are.

Best for: Your high-demand items and situations where suppliers aren’t 100% reliable. Pairs beautifully with demand forecasting and ABC analysis (perfect for those A items). Keep in mind that JIT and safety stock work against each other since one minimizes inventory while the other adds buffer stock.

EOQ is a formula that determines the ideal order quantity by balancing ordering costs against storage costs.

Best for: Products with predictable demand and stable costs. Works great alongside demand forecasting and ABC analysis. Skip it if bulk discounts make ordering larger quantities way cheaper than the formula suggests.

You pre-bundle individual items into ready-to-ship packages before orders come in, so instead of picking three separate items, you grab one pre-made kit.

Best for: Products that regularly sell together. Think gift sets, morning routines, or subscription boxes. This fits nicely with other methodologies. You can use demand forecasting to figure out which kits to create and EOQ to decide how many.

With dropshipping, you don’t hold any inventory. When someone orders, you buy it from a supplier who ships directly to your customer. You’re the connector, not the warehouse.

Best for: Testing new products or starting out without much capital. Since you don’t control inventory, you can’t really use most other methods here. That said, lots of businesses do a hybrid. Dropship the slow movers while keeping your best sellers in stock.

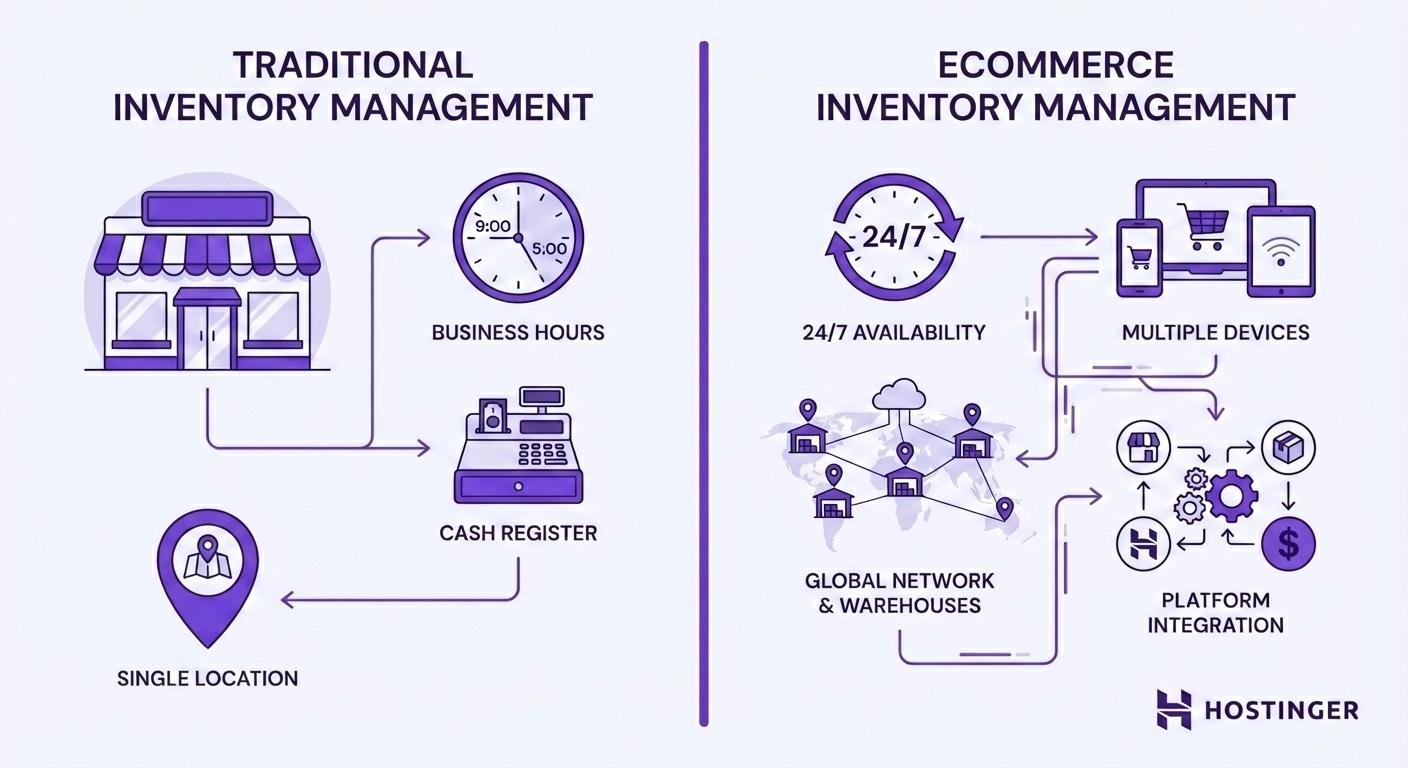

While both ecommerce and brick-and-mortar inventory management share the same goal of having the right products at the right time, the execution looks quite different in practice.

Speed and timing

Traditional retail operates on a relatively predictable rhythm with business hours and scheduled shipments.

Ecommerce never sleeps. Orders come in 24/7, and customers expect rapid fulfillment. Your inventory system needs to be updated in real-time across all sales channels, not just at closing time.

Accuracy requirements

In a physical store, customers see what’s available on the shelf.

Online, you have the advantage of automation, but you need to sync your inventory with your ecommerce platform so product pages update instantly to show out-of-stock items. Customers can still view products, add them to wishlists, and sign up for restock alerts.

SKU management

Traditional stores are limited by physical shelf space, maybe carrying hundreds or a few thousand products.

Ecommerce stores often manage tens of thousands of SKUs, each with variations in size, color, and style that require separate tracking.

Returns management

Physical stores might handle returns at the register, but ecommerce returns are a whole different beast.

Products ship back to you, need inspection and processing, must be returned to available inventory (if they’re still sellable), and tracked through the entire reverse logistics journey.

Integration demands

Traditional inventory management might integrate with your point-of-sale system and accounting software.

Ecommerce inventory management needs to sync with your website, marketplace listings (such as Amazon, eBay, or Etsy), shipping carriers, warehouse management systems, accounting software, CRM platforms, and more.

Geographic complexity

A traditional store has one location (or maybe a few). Ecommerce businesses often distribute inventory across multiple warehouses, use third-party ecommerce fulfillment services, employ dropshipping for some products, and need to track everything in real-time across all these locations.

You’re managing a complex network, not just one stockroom.

The future of inventory management is already here, and it’s pretty exciting.

AI and machine learning

We’re seeing how AI in ecommerce is transforming demand forecasting from educated guessing into predictive science.

AI systems analyze your sales history, weather patterns, social media trends, and more to predict demand with impressive accuracy.

These systems learn over time, anticipating things like umbrella sales before the rain starts or beachwear spikes weeks before seasonal patterns suggest.

IoT inventory tracking

This is the use of connected devices, so your warehouse can essentially manage itself and provide instant alerts about inventory movements or opportunities.

Think smart shelves that detect low stock, RFID tags that track items without manual scanning, or sensors that monitor storage conditions.

Physical automation

Automation is becoming a reality with robots picking and packing orders, automated vehicles moving inventory within warehouses, drones conducting inventory counts, and machine learning optimizing warehouse layouts.

The result? Faster, more accurate fulfillment operations.

Omnichannel fulfillment

Advanced fulfillment systems that treat all inventory as one unified pool rather than separate stock for your website, physical stores, and marketplaces.

This enables exciting capabilities like:

Sustainable inventory practices

Consumers increasingly care about environmental impact, and effective inventory management can help you meet those expectations.

Better forecasting means less waste, smarter packaging uses fewer materials, choosing eco-friendly suppliers makes a real difference, and thoughtful shipping decisions are better for the planet.

Plus, they often save you money through improved efficiency.

Your next steps

Managing ecommerce inventory might never be simple, but with the right systems and strategies, it’s absolutely manageable.

Just starting out? Set up basic inventory tracking with your ecommerce platform, use FIFO for stock rotation, and start collecting sales data.

Already selling? Review the last three months of sales, identify your A/B/C items, and set reorder points for your top 20% of products.

Ready to scale? Invest in inventory management software like Cin7 or Katana that syncs with your sales channels and implements demand forecasting.

The businesses thriving today are the ones that improve one step at a time. Pick one thing and implement it this week. Progress beats perfection.