Feb 11, 2026

Simon L.

17min Read

Ecommerce fulfillment services are the operational processes that move an online order from checkout to delivery and handle returns.

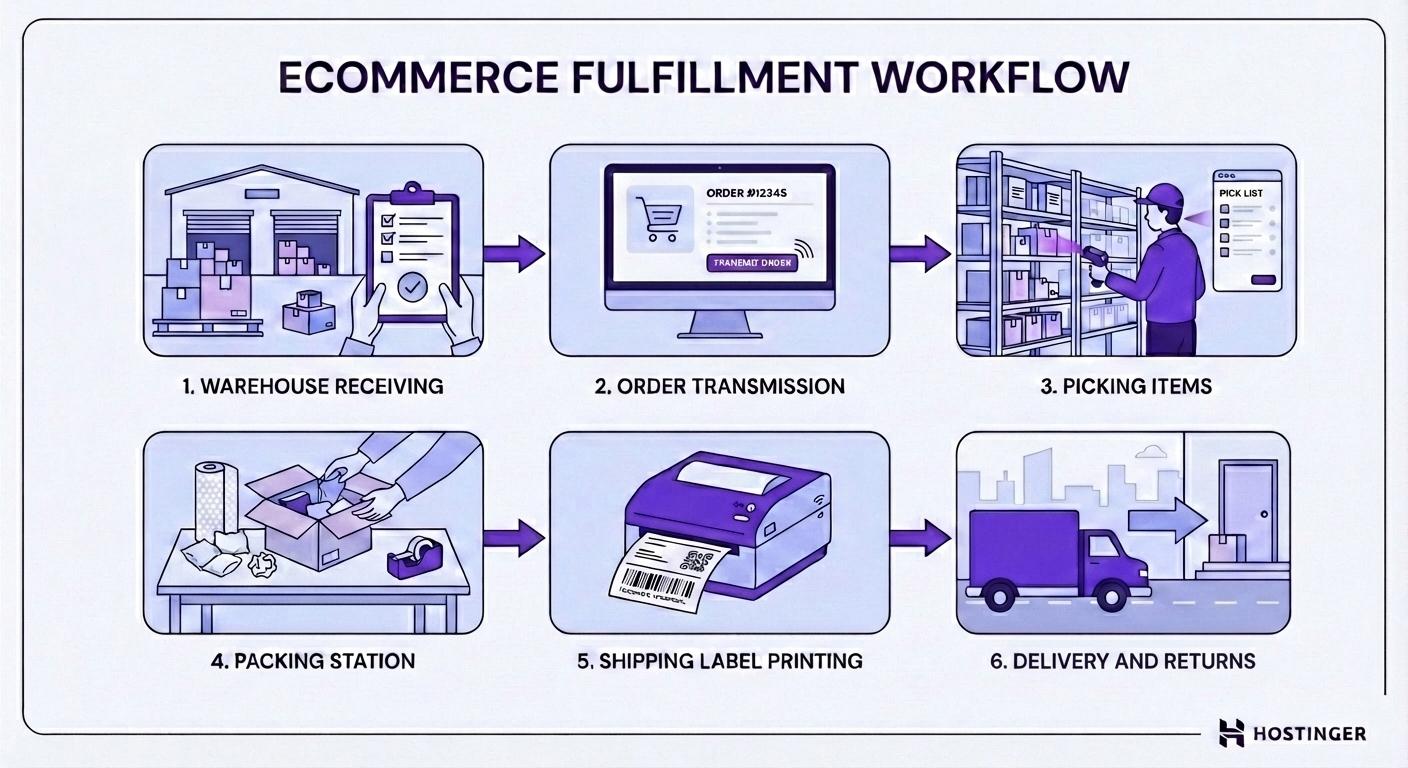

They cover everything from receiving your inventory and storing it safely to picking the right items when orders come in, packing them properly, creating shipping labels, handing packages to carriers, and processing returns.

It’s important to distinguish fulfillment from logistics: Logistics is the plan; fulfillment is the execution.

If you decide to store inventory in Texas to reach most customers in 2–3 days and negotiate rates with UPS, that’s logistics.

When order #4821 comes in, and a warehouse worker picks two SKUs, packs the box, prints the label, and ships it with tracking, that’s fulfillment.

Who typically uses fulfillment services?

The most common approach is outsourcing to a third-party logistics provider (3PL), which is a company that specializes in storing inventory and shipping orders for multiple clients.

Ecommerce fulfillment services typically include storing your products, processing and packing orders, coordinating shipping with carriers, and handling returns.

In other words, fulfillment services focus on storage and order execution. They don’t handle manufacturing your products, marketing and sales, managing your online store, or customer support—aside from providing tracking and shipment status.

Think of fulfillment services as layers that work together:

Distributed fulfillment

One powerful feature many 3PLs offer is distributed fulfillment. This is when they store your inventory in multiple warehouses across different regions.

Why does this matter? Shorter distances mean faster delivery and lower shipping costs. Instead of shipping every order from California, you might have inventory in California, Texas, and New Jersey, automatically routing each order to the closest facility.

People use fulfillment and logistics interchangeably, but they’re different, and knowing the difference helps you understand who’s responsible for what.

Ecommerce logistics is the broader strategy and coordination of moving goods. It includes transportation planning, carrier contract negotiations, network design, demand forecasting, and supply chain optimization.

Logistics is about the “what,” “when,” and “where” decisions. Examples include negotiating shipping rates with DHL and deciding where to locate warehouses based on customer density.

Ecommerce fulfillment is the execution layer. It’s the actual work of receiving, storing, picking, packing, and shipping individual orders.

Fulfillment is the “how” that makes logistics plans real. This involves printing a shipping label for order #4582, picking three products from shelf locations, and packing the box.

Who owns what

If you sell on Amazon, you’ve probably heard of Fulfillment by Amazon (FBA). It’s a popular fulfillment option, but it’s not the same as working with an independent 3PL.

Amazon FBA is Amazon’s platform-tied fulfillment service. You send inventory to Amazon’s warehouses, and they pick, pack, and ship orders to customers who buy on Amazon.com.

FBA also makes your products eligible for Prime two-day shipping, which can boost sales.

The catch? FBA is designed for Amazon’s marketplace. If you also sell on Etsy or your own website, FBA doesn’t easily support those channels.

Amazon’s packaging is Amazon-branded, your storage costs follow Amazon’s fee schedule, and you’re subject to storage limits and long-term storage fees if inventory sits too long.

Independent 3PL fulfillment works across all your sales channels, including your online store, Amazon, eBay, and any other channels where you sell.

You get to use branded packaging, set your own customer service standards, and avoid platform-specific storage constraints.

Here are the key decision factors to choose between FBA and 3PL:

Want to compare models? Check out our guide on dropshipping vs Amazon FBA.

Here’s the fulfillment workflow, from the moment you send inventory to a warehouse until a customer receives their order.

There’s no single right way to handle fulfillment. The best model depends on your order volume, product type, margins, and growth trajectory.

You handle everything yourself, including inventory management, order picking, box packing, label printing, and delivering packages to carriers.

Many businesses start by fulfilling orders from home, a garage, or a small office. To get going, you’ll need shelving, packing materials, a shipping scale, a label printer, and carrier accounts.

When self-fulfillment works:

Self-fulfillment is especially common when starting an ecommerce business without funds, since it eliminates the upfront cost of working with a 3PL.

You’re trading your time for money, which makes sense when you’re bootstrapping and need to keep every dollar working for you.

Breaking points that push businesses to 3PL:

You outsource warehousing and order fulfillment to a specialized company. You send them inventory in bulk, and they handle receiving, storage, picking, packing, and shipping individual customer orders.

Standard services you should expect:

How 3PL pricing typically works:

Service level agreements (SLAs) matter:

Good 3PLs commit to performance standards in writing.

Look for commitments such as 99.5% or higher order accuracy, same-day processing for orders received by the cut-off time, regular cycle counts for inventory accuracy, and clear support response times.

When 3PL makes sense:

Want help choosing partners? Learn about how to choose vendors for an ecommerce website.

You don’t hold any inventory. When a customer orders from your store, you forward the order to a supplier, which ships it directly to the customer. You never touch the product.

This completely changes the fulfillment chain:

Traditional fulfillment goes Supplier → Your warehouse → Customer.

Dropshipping goes Supplier → Customer, with you coordinating in the middle.

What you lose control over:

When dropshipping fits:

When dropshipping becomes risky:

If you dropship, be transparent: show realistic delivery windows on product pages (15-30 days, not two to three days), provide tracking info promptly, and set proper expectations about packaging and return times.

Ready to explore more? Here’s how to start a dropshipping business.

A 4PL doesn’t operate warehouses or ship orders itself – they orchestrate your entire logistics network by managing multiple 3PLs, designing a distribution strategy, and coordinating carriers.

Think of them as a logistics control tower that handles network design, carrier negotiations, technology integration, and performance reporting across all your fulfillment partners.

You’ll know you need one when scaling an ecommerce business to enterprise volume (typically 5+ warehouses, tens of thousands of monthly orders), where coordinating multiple fulfillment partners becomes a full-time job.

When evaluating fulfillment providers, focus on the practical realities that actually matter in day-to-day operations.

Location determines everything about shipping speed and cost. A package traveling 300 miles costs less and arrives faster than one crossing 1,500 miles.

If most of your customers are in one region and your warehouse is on the opposite side of the country, you’re paying more and delivering slower than you need to.

Common network setups:

Look at your order data from the past three to six months. Where do your customers actually live? If 60% of orders go to California, Texas, and Florida, you want warehouses that cover those markets efficiently.

Questions to ask providers:

Manual order entry is a nightmare, so your fulfillment provider needs to communicate directly with your store, and this needs to happen reliably.

Real-time inventory sync prevents selling out-of-stock products, holding back inventory across channels, and making manual inventory adjustments every time you get an order.

Must-have integrations:

To ensure everything runs smoothly, verify that the integration meets your specific needs, especially for complex workflows such as split orders, gift messages, or custom fields.

If you run multiple stores, confirm they can integrate all of them, and ask how often data is updated, as some platforms limit API calls, which can create sync delays.

Questions to ask:

Shipping options and carrier rate management determine which carriers you can use, available service levels (ground, express, international), and the rates you’ll pay.

Most 3PLs have negotiated rates below retail carrier costs. They either pass through actual carrier costs with no markup, offer their negotiated volume discounts (usually savings for you), or charge blended rates (flat rates per zone).

Carriers calculate shipping costs based on whichever is higher: the package’s actual weight, its dimensional weight (based on box size), or how far it travels. Using boxes that are larger than necessary increases dimensional weight and raises shipping costs.

For international shipping, you need to clarify who pays duties and taxes, who handles customs documentation, and how international returns are handled.

Questions to ask:

Fast returns processing builds trust, while slow returns processing frustrates customers. But returns aren’t just about customer satisfaction.

They also affect your cash flow, and the faster a return is inspected and restocked, the faster you can resell it or issue a refund.

When a return arrives, the fulfillment center inspects it and decides to:

You need clear rules about what counts as sellable for your products. A minor scuff might be fine for a $15 phone case, but unacceptable for a $500 luxury item.

Your returns SLA should include inspection turnaround time (within two business days), restock timeframe (inventory updated within 24 hours), and photo documentation for high-value items.

Questions to ask:

Value-added services (VAS) are services beyond standard pick, pack, and ship.

Common options include kitting (assembling multiple items into a single SKU), subscription box assembly, custom labeling, gift wrapping, inserts (promotional cards, thank-you notes, samples), and FBA prep.

VAS can improve your business by increasing average order value through curated sets, enabling subscription revenue, improving unboxing experience to build brand loyalty, and driving discovery through samples.

On the other hand, VAS introduces operational risk: more touches increase the likelihood of mistakes, complex assembly adds processing time, and complex instructions can be misinterpreted.

If you need VAS, provide detailed documentation including step-by-step instructions with photos, exact packaging specifications, clear quality standards, and physical samples of the finished product.

Questions to ask:

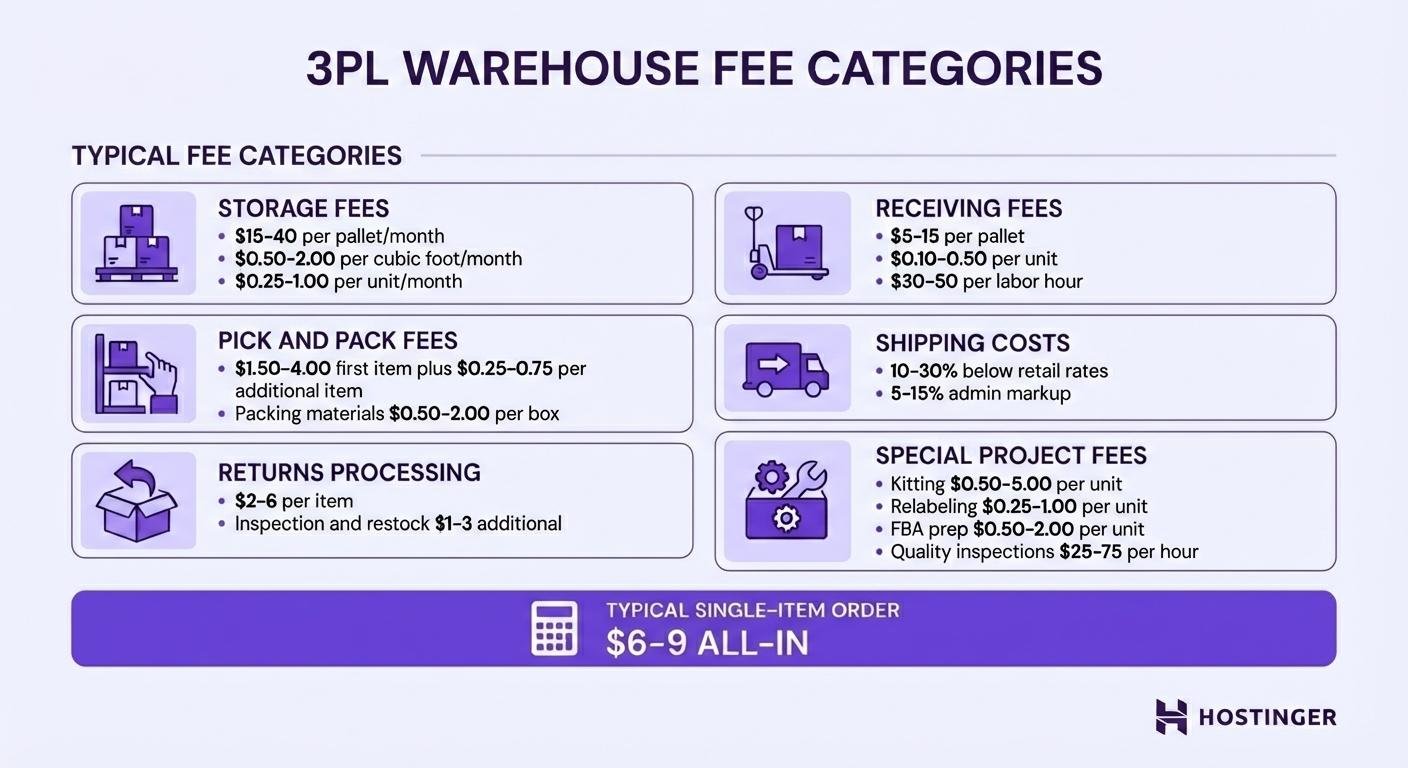

Fulfillment costs depend on order volume, product characteristics, and provider efficiency. The goal is to find the best-value provider rather than the most affordable option.

Cheap fulfillment that ships late or makes mistakes costs more in lost customers than paying for quality.

Storage fees: You pay to store inventory in their warehouse. Common methods include $15-40 per pallet per month, $0.50-2.00 per cubic foot per month, or $0.25-1.00 per unit per month. Location, product characteristics (hazmat or temperature control), and how long items sit all influence costs.

Receiving fees: Charged when your inventory arrives, typically $5-15 per pallet, $0.10-0.50 per unit, or $30-50 per labor hour for special handling.

Pick and pack fees: Charged per order shipped, usually $1.50-4.00 for the first item plus $0.25-0.75 per additional item, with packing materials adding $0.50-2.00 per box.

Shipping costs: Either actual carrier costs (transparent) or negotiated rates, usually 10-30% below retail. Most 3PLs add no markup or add 5-15% to cover admin costs.

Returns processing: Receiving and inspecting returns typically costs $2-6 per item, with inspection and restock included or costing $1-3 additional.

Special project fees: Custom work like kitting runs ($0.50-5.00 per unit), relabeling ($0.25-1.00 per unit), FBA prep ($0.50-2.00 per unit), or quality inspections ($25-75 per hour).

What you’ll actually pay

For a typical single-item order with standard packaging shipped ground to a mid-distance destination, expect $6-9 all-in with a good 3PL, including pro-rated storage, pick and pack, and shipping.

Multi-item orders or express shipping will push costs higher, while high-volume accounts often negotiate better rates. The key is understanding your specific order profile rather than optimizing for the lowest per-item fee.

When talking to providers, here are the details you need to have to get accurate quotes:

The more accurate your data, the more accurate the quote.

Monthly minimums: Many 3PLs charge $200-1,000/month regardless of actual volume, or require a minimum number of orders per month. If you’re seasonal or growing slowly, minimums can eat into your margins during slow months.

Long-term commitments: Some contracts require 12-month minimum terms with penalties for early termination, or a 30-90-day cancellation notice. Better contracts offer month-to-month terms or 30-day notice periods.

Seasonal surcharges: Peak season, usually around the holidays, costs more through storage surcharges (20-50% increases September through December), labor surcharges during peak weeks, and carrier surcharges. Ask for peak season pricing upfront so you can budget.

Unexpected billing issues

Beyond these contractual terms, watch for common billing issues that can inflate your costs:

Contract checklist before signing

Read the contract carefully and verify these terms before committing:

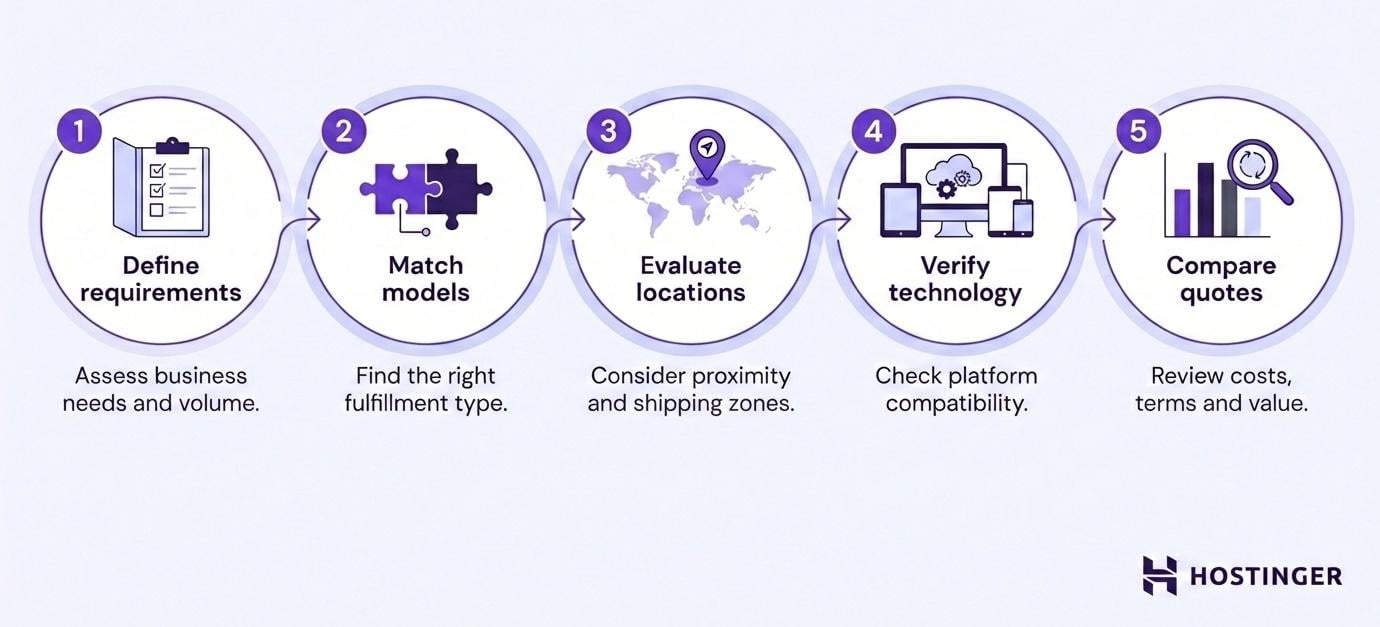

Choosing the right fulfillment provider is about finding the one that fits your specific requirements, budget, and growth trajectory.

Here’s a practical framework.

Before you talk to any providers, document exactly what you need. Write down your average daily orders (current average and peak day volume) and expected growth.

List your SKU count and product characteristics, such as size, weight, fragility, temperature requirements, or hazmat needs.

Note any special handling requirements, packaging needs, and target ship times (same-day, next-day, or two-day).

Define service requirements:

Document your channel requirements:

Based on your requirements, decide which model fits.

Choose self-fulfillment if you’re shipping fewer than 20-50 orders per day, have storage space and time to pack, need absolute control, or have margins too thin for 3PL fees right now.

Choose 3PL fulfillment if you’re consistently shipping 50+ orders per day, need multiple warehouse locations for speed, want to spend time on growth instead of packing, or sell across multiple channels and need centralized inventory.

Choose dropshipping if you’re testing products, have limited capital, or you’re okay with less control over packaging and quality.

You can also consider hybrid models: best-sellers go with 3PL while testing other products with dropshipping, or self-fulfill for local orders while using 3PL for distant orders.

Start by looking at your last three to six months of order data to understand where your customers actually are. Calculate what percentage of orders go to each region or state and identify your top 20 destination ZIP codes.

Next, validate speed claims by giving providers your top destinations and asking them to show transit maps from each warehouse. Calculate what percentage of your orders would arrive in one, two, or three days, then compare that to your shipping promise.

Find out about carrier pickup schedules (daily or multiple times per week) and weekend handling (most don’t process Saturdays or Sundays).

Finally, test their service claims with sample orders. Ask: “If I sent you an order at 10 am on Tuesday to ZIP code 90210, when would it arrive?”

Do this for several important destinations to see real-world performance, not just theoretical transit times.

Fulfillment relies on software working smoothly, and if it doesn’t, you’ll spend hours on manual fixes. Before you commit to a provider, ask them to show you their system in action.

Request a demo showing live inventory views in their portal, how an order flows from your store to their system, where you’d see order status and tracking, and how you’d handle exceptions like wrong items shipped.

Ask about the reports you’d receive and how often, how you’d add new products or update SKU data, and what alerts you’d receive for low stock or delays.

If they can’t demo these basics or the system looks clunky, that’s a red flag.

Here are the key systems you need to see:

These are the must-have reports:

You’ll get wildly different quotes if you’re not comparing apples to apples.

Start by creating a standard order profile to use with every provider:

Provide identical assumptions to all providers, such as the same monthly order volume, SKU count, storage needs, destination mix, return rate, and special services. This ensures you’re comparing the same scenario across the board.

Don’t just compare pick-and-pack fees in isolation – you need the true total cost per order to make an informed decision. Request “all-in cost per order” that includes storage, receiving costs, pick-and-pack fees, average shipping cost, returns processing, and account fees or minimums.

Once you have the details, score each provider on:

The best choice balances cost, speed, and reliability for your specific needs. Don’t optimize for just one variable, like cost, since cheap fulfillment that ships late costs more in lost customers than paying for quality.

Once you’ve narrowed it to the finalists, get everything in writing: a complete fee schedule with exact rates, contract terms (length, minimums, cancellation), SLAs (order accuracy, same-day ship rate, support response time), peak season pricing, and an escalation process.

Even with a great provider, things can go wrong if you don’t manage the relationship well.

Without clear ownership, customers email both you and the 3PL, getting conflicting information. Orders ship late, but there’s no clear SLA for on-time delivery, so you can’t hold anyone accountable.

The fix is to document who owns what in writing.

You’re responsible for maintaining accurate SKU data, providing inventory forecasts, handling customer service inquiries, managing return policy decisions, and providing packaging specifications.

Your 3PL is responsible for accurate inventory counts, same-day shipping for orders received by cut-off, 99.5%+ order accuracy, returns inspection within two business days, and providing tracking numbers within one hour.

Create an ownership map document that specifies who is responsible for each scenario, including contact names, response timeframes, and approval thresholds.

Review it quarterly to update contacts, adjust processes based on what’s working, and address any gray areas that have caused confusion.

If you list a product as 8 ounces (225g) when it’s actually 14 ounces (400g), the 3PL uses the wrong box size, pays dimensional weight penalties, and bills you for the difference.

If you wanted branded tissue paper in every box but didn’t specify it, orders go out in plain packaging, and customers notice.

What you need to do is maintain a detailed SKU master file with photos.

For every product, include the SKU code, product name, exact dimensions and weight, fragility level, special handling requirements, case pack quantity, and barcode.

For packaging, specify the box size, required cushioning materials, inserts to include, branded materials, gift options, and any special instructions.

Provide photos of the correct packing configuration, the finished packed box (inside and outside views), and any branded materials. Update this file every time you add a product or change packaging.

Without clear standards, everything gets quarantined, and refunds take weeks because you’re manually reviewing photos.

Or the 3PL restocks everything automatically, and you discover you’ve been reselling damaged products, creating even more returns.

To address this, set clear return rules and inspection standards upfront.

Define your return window (30, 60, or 90 days), condition requirements (unopened, gently used, no restrictions), who pays return shipping, refund timing (immediate or after inspection), and restocking fees.

Create inspection standards:

Monitor return rate, return reasons, restock rate, days to restock, and cost per return. These numbers reveal patterns that help you spot product quality issues, identify misleading descriptions, catch size chart problems, and understand the true cost of your returns process.

If any metric spikes suddenly, investigate immediately, as it’s usually a signal that something’s wrong upstream.

You’ve learned the models, the costs, the evaluation criteria, and the common mistakes. Now let’s turn that into action.

Here’s what your workflow looks like:

Align fulfillment with storefront messaging

If you’re just starting out, learn how to launch an online store to get the basics right first. At every stage of growth, one rule stays constant: your fulfillment capabilities need to align with what you promise customers.

If you promise two-day shipping on your site, make sure your 3PL can actually deliver that. If you can only do three to five days reliably, say so.

If returns take five business days to inspect and restock, don’t promise instant refunds.

If you’re adding international fulfillment, update product pages with delivery estimates and duties info.

Fulfillment isn’t glamorous, but it’s the backbone of customer satisfaction in ecommerce. Get it right, and you’ll build trust, reduce costs, and free yourself to focus on growth.

Get it wrong, and you’ll spend your days apologizing to angry customers. Choose wisely, document everything, and don’t be afraid to change providers if they’re not delivering on their promises.